Reliability Description

Reliability describes the endurance of the device. Anlogic Infotech tests the device mainly through different targeted experiments under the JESD47 test syllabus, including:

Reliability related to wafer process (HCI, BTI, TDDB, GOI, EM, SM…… ...)

Circuit-related reliability (ESD, Latch-up, HTOL, LTOL ……)

Package-related reliability (PC, TCT, HTSL, (U) HAST ……)

Board-level related reliability (BTC ……)

These test conditions are far more severe than the application scenarios. By stimulating the potential weaknesses of semiconductor wafers and packages, they are used to eliminate early defects of the device, check its reliability indexes, evaluate its service life and enhance its reliability level. The test data will be collected to illustrate the reliability of the device, as well as to close the loop by meticulously analyzing the cause of each failure of a nonconforming product and taking effective corrective action.

Anlogic Infotech is currently referring to the following specifications (please refer to the official JEDEC website for the latest version):

| NO | Document# | Standard State | Standard Project |

|---|---|---|---|

| 1 | JESD47 | Latest version | STRESS-TEST-DRIVEN QUALIFICATION OF INTEGRATED CIRCUITS |

| 2 | JESD22-A113 | Latest version | Preconditioning of Nonhermetic Surface Mount Devices Prior to Reliability Testing |

| 3 | JESD22-A100 | Latest version | Cycled Temperature-Humidity-Bias with Surface Condensation Life Test |

| 4 | JESD22-A101 | Latest version | Steady-State Temperature-Humidity Bias Life Test |

| 5 | JESD22-A102 | Latest version | Accelerated Moisture Resistance - Unbiased Autoclave |

| 6 | JESD22-A103 | Latest version | High Temperature Storage Life |

| 7 | JESD22-A104 | Latest version | Temperature Cycling |

| 8 | JESD22-A106 | Latest version | Thermal Shock |

| 9 | JESD22-A110 | Latest version | Highly Accelerated Temperature and Humidity Stress Test (HAST) |

| 10 | JESD22-A118 | Latest version | Accelerated Moisture Resistance - Unbiased HAST |

| 11 | J-STD-002D | Latest version | Solderability Tests for Component Leads |

| 12 | JESD22-B115 | Latest version | Solder Ball Pull |

| 13 | JESD22-B116 | Latest version | Wire Bond Shear Test Method |

| 14 | JESD22-B117 | Latest version | Solder Ball Shear |

| 15 | JESD78 | Latest version | IC LATCH-UP TEST |

| 16 | JESD22- A108 | Latest version | TEMPERATURE, BIAS, AND OPERATING LIFE |

| 17 | JS-001 | Latest version | Electrostatic Discharge Sensitivity Testing Human Body Model (HBM) -Component Level |

| 18 | JS-002 | Latest version | ESDA/JEDEC JOINT STANDARD FOR ELECTROSTATIC DISCHARGE SENSITIVITY TESTING – CHARGED DEVICE MODEL (CDM) – DEVICE LEVEL |

| 19 | J-STD-020 | Latest version | Moisture/Reflow Sensitivity Classification for Non-hermetic Surface Mount Devices (SMDs) |

| 20 | JEDEC-SPP-024 | Latest version | Reflow Flatness Requirements for Ball Grid Array Packages |

| 21 | JESD89-3 | Latest version | TEST METHOD FOR BEAM ACCELERATED SOFT ERROR RATE |

| 22 | JESD85 | Latest version | METHODS FOR CALCULATING FAILURE RATES IN UNITS OF FITS |

The Endurance of the Product

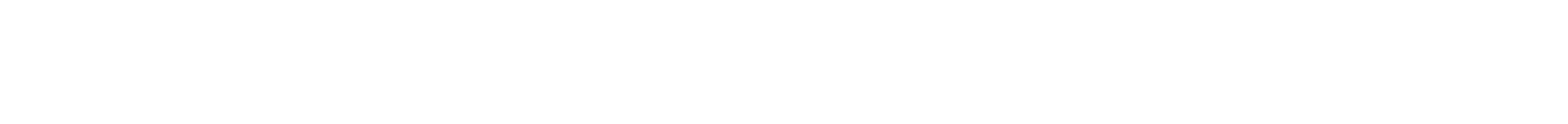

The lifespan of a device refers to the period during which it meets all performance indexes or acceptance requirements in the product specifications under the specified stress environment. Typically, the weakest part of a device determines its lifespan. When the device's failure rate conforms to Weibull distribution, the time when the cumulative failure rate of a device is below 63.2% is defined as the characteristic life of a device. We use the characteristic life curve (bathtub curve) to describe it, which consists of the following three parts:

The first part is the failure rate that decreases with time, which is called early failure.

The second part is the approximately fixed failure rate, which is called random failure.

The third part is the failure rate that increases with time after exceeding its design life, which is called wear out.

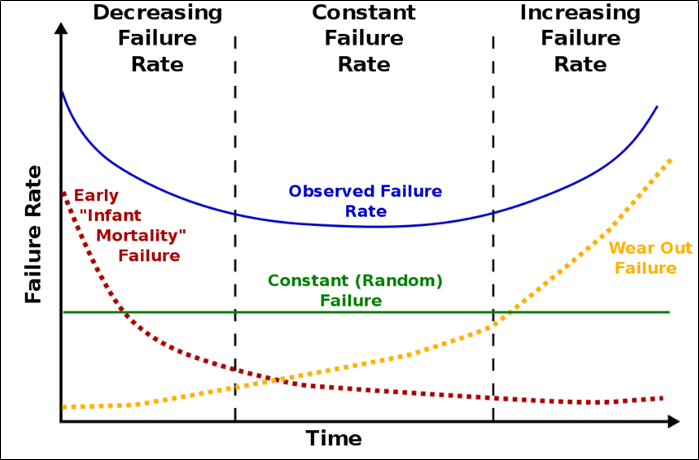

Anlogic Infotech introduces JESD85 (Methods for Calculating Failure Rates in Units of FITs) to standardize the measurement of product failure.

The calculation is described as follows:

Anlogic Infotech evaluates the reliability of devices running in different operating environments based on a set of generally acceptable stress test criteria that the devices can withstand to ensure good reliability performance in the application.

Reliability Data

Anlogic Infotech has an extremely reliable monitoring and prevention program to ensure that all products it has launched are of the best quality. Anlogic Infotech performs all major reliability tests on each process using state-of-the-art equipment and technology. The results of the stress test in the accelerated environment can be extrapolated to standard operating conditions to predict effective service life and ensure that our products have the highest reliability ratings in the industry.

For detailed reliability data, please contact the sales center or distributor.